Nomex® Fire-Resistant Fiber — a Long Lifecycle of Protection

Article | July 11, 2019

DuPont™ Nomex® fire-resistant fiber offers excellent wear life that helps lead to a greater overall value.

Nomex® fire-resistant fiber is a premium material that can help provide very favorable results to a bottom line. In order to calculate return on investment when it comes to flame-resistant garments, it’s important to consider the initial cost divided by the number of wears.

For example, a flame-retardant-treated (FRT) cotton garment that costs less may initially seem like a better value than a garment of Nomex®. However, over the course of time, based on a variety of factors, a garment of Nomex® is a good investment.

Professional launderers have already learned the benefits of Nomex®. Protective apparel made of Nomex® is so durable that industrial launderers estimate that it may last for five years and be washed and worn at least 125 times without compromising its protection, shape and professional appearance. In contrast, garments of FRT cotton can be washed and worn an average of only 25–40 times. Therefore, industrial launderers can charge up to 40% more for rental programs of FRT cotton garments than for rental programs of Nomex®.

Durability of fabrics made of Nomex® fire-resistant fiber:

Protective apparel made of Nomex® is so durable that industrial launderers estimate that it may last for five years and be washed and worn at least 125 times without compromising its protection, shape and professional appearance. In contrast, garments of flame-retardant-treated (FRT) cotton can be washed and worn an average of only 25–40 times.

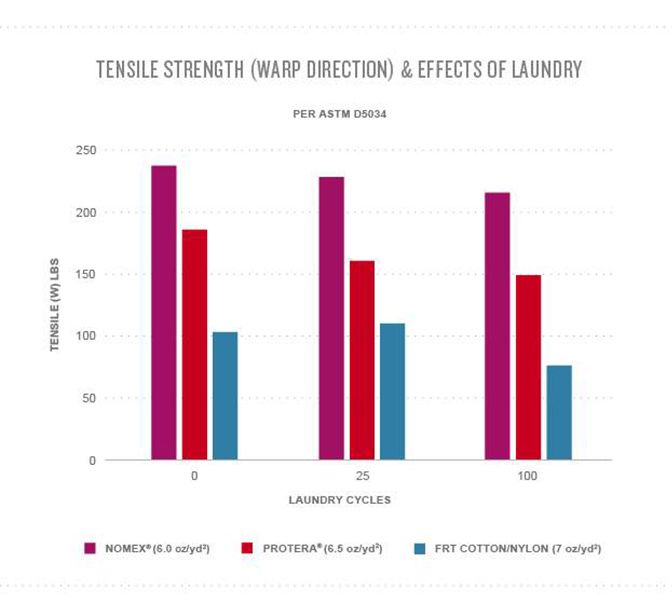

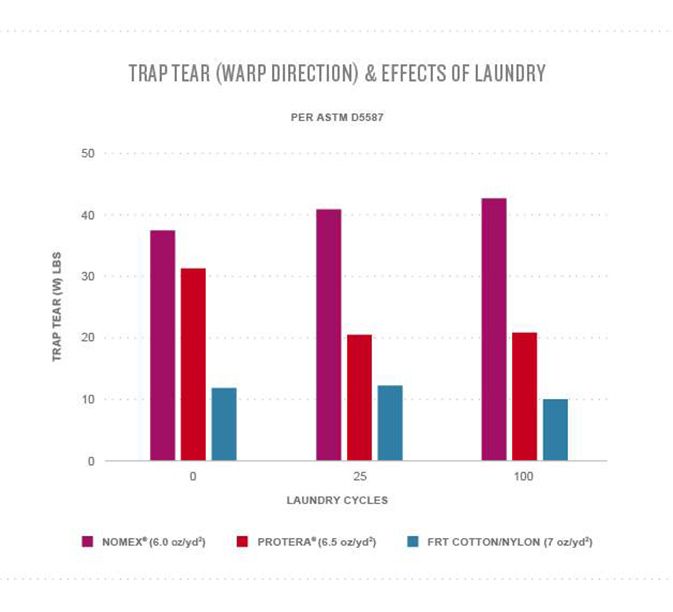

Nomex® and Protera® performance through launderings.

In thermal protective garments, a single rip or tear can mean replacing the entire garment. However, because DuPont™ Nomex® offers twice the strength and tear resistance of FR cotton nylon blends, these garments can remain effective and in service longer.

How a garment will respond to a snag or a rip.

Nomex® appearance retention:

Shrinkage is an important factor to consider when evaluating garment durability, comfort, and appearance. In a laboratory test, fabrics of Nomex® fire-resistant fiber experienced low shrinkage, and then maintained their size and shape through many subsequent launderings.

Nomex® ease of care:

In addition, garments made of Nomex® have a better color-fastness and appearance retention versus FRT cotton/nylon, with superior professional appearance throughout the lifecycle of the garment. And they rarely need pressing; they come out of the dryer ready to wear, in contrast to FRT cotton garments, which wrinkle significantly after washing and drying.

Nomex® thermal performance:

The inherent flame resistance of Nomex® thermal technology means protection is not washed out or worn away.

Nomex® for thermal protection, superior lifecycle and durability:

Garments made with flame resistant Nomex® fiber are extremely durable and resist abrasion and tears. They’re also an excellent value, lasting three to five times longer than other standard and protective fabrics, including 100% cotton and flame-retardant treated (FRT) cotton. In lease, rental, and purchase programs, for example, the excellent wear life of garments of Nomex® can help contribute to bottom-line savings.