DuPont’s Larkin re-roof project premiers reduced-GWP Styrofoam™ Brand Extruded Polystyrene (XPS) Insulation for an improved sustainability profile

PROJECT SUMMARY

| Featured product: | STYROFOAM™ Brand XPS (new grey reduced-GWP formulation) |

| Project type: | PMR and conventional re-roof |

| Completion date: | 2019 |

| Owner: | DuPont |

| R-value* before re-roof: | R-20 |

| R-value after re-roof: | R-30 |

| Total project size: | 165,800 square feet |

Performance Above. Innovation Below.

In the fall of 2019, when the time came to re-roof the 200 Larkin building located on its DuPont North/Larkin campus in Midland, Mich., DuPont seized the opportunity to put its reduced global warming potential (GWP) grey Styrofoam™ Brand Extruded Polystyrene (XPS) Rigid Foam Insulation to the test. Some of the scientists and sustainability experts who had a hand in the product innovation work in these very buildings.

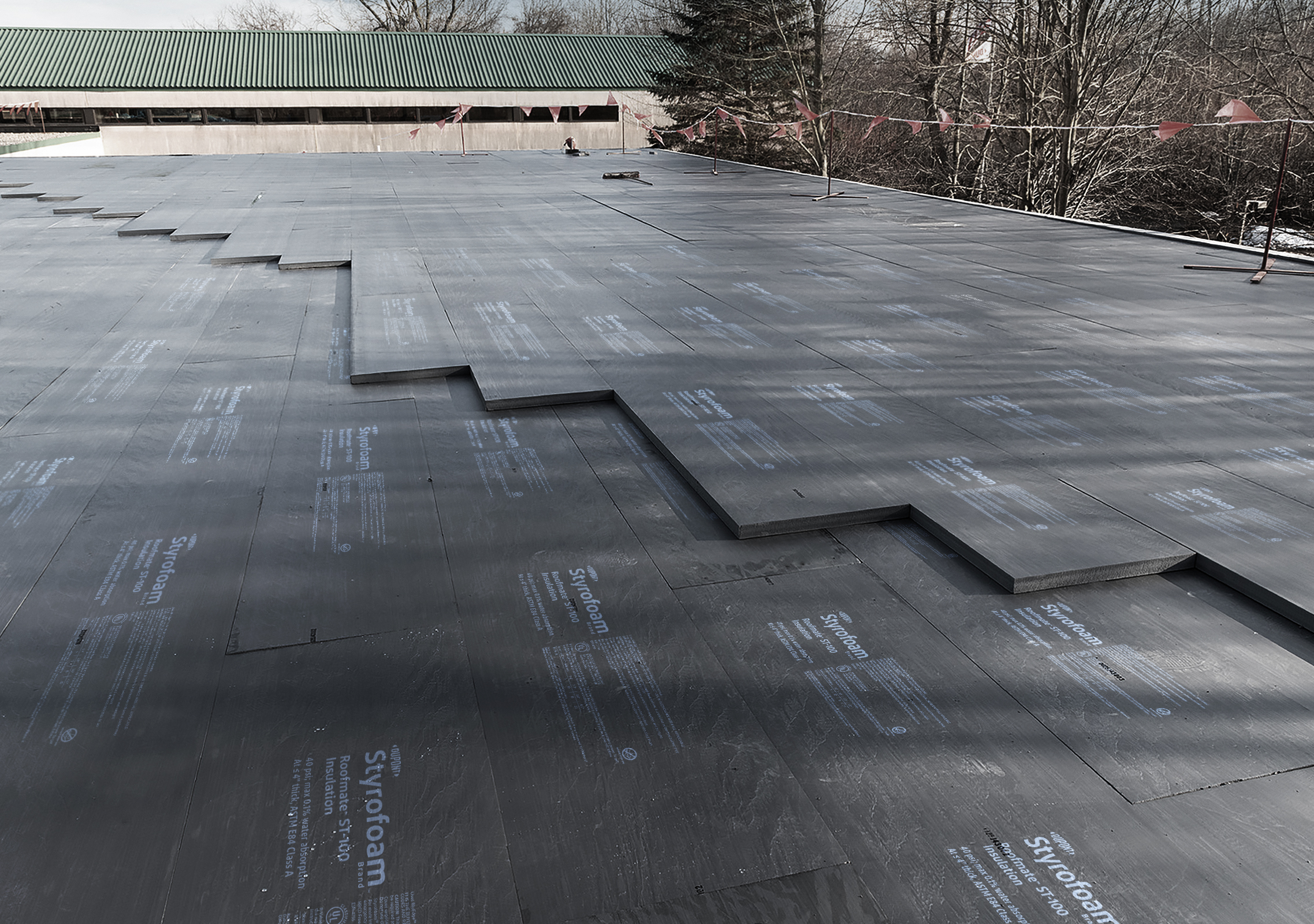

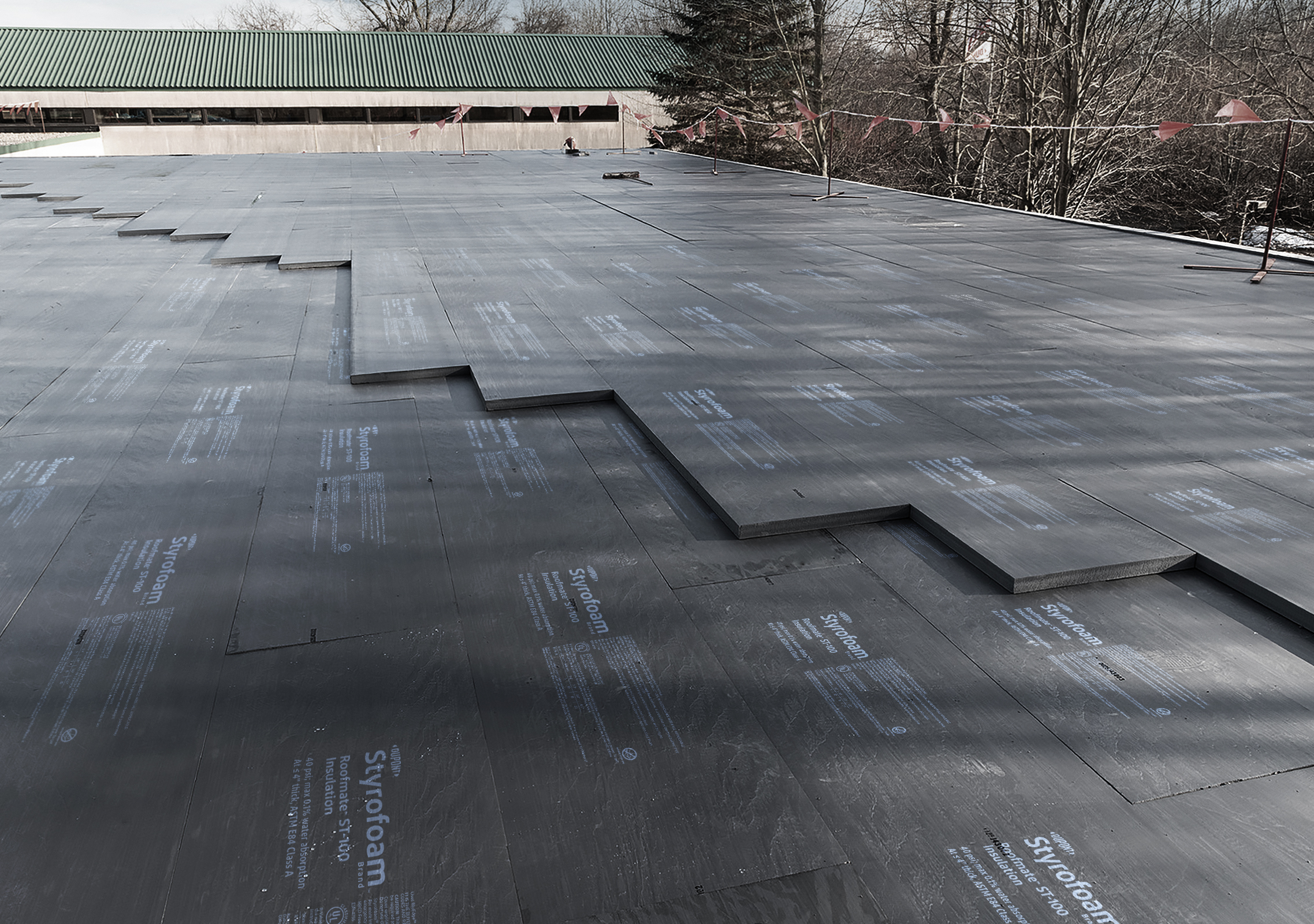

The project entailed removing ballast and two layers of blue Styrofoam™ Brand Extruded Polystyrene (XPS) Rigid Foam Insulation and then adding a new roof membrane, upgrading the insulation and adding an additional insulation layer. The roof had been in service for the last 30 years.

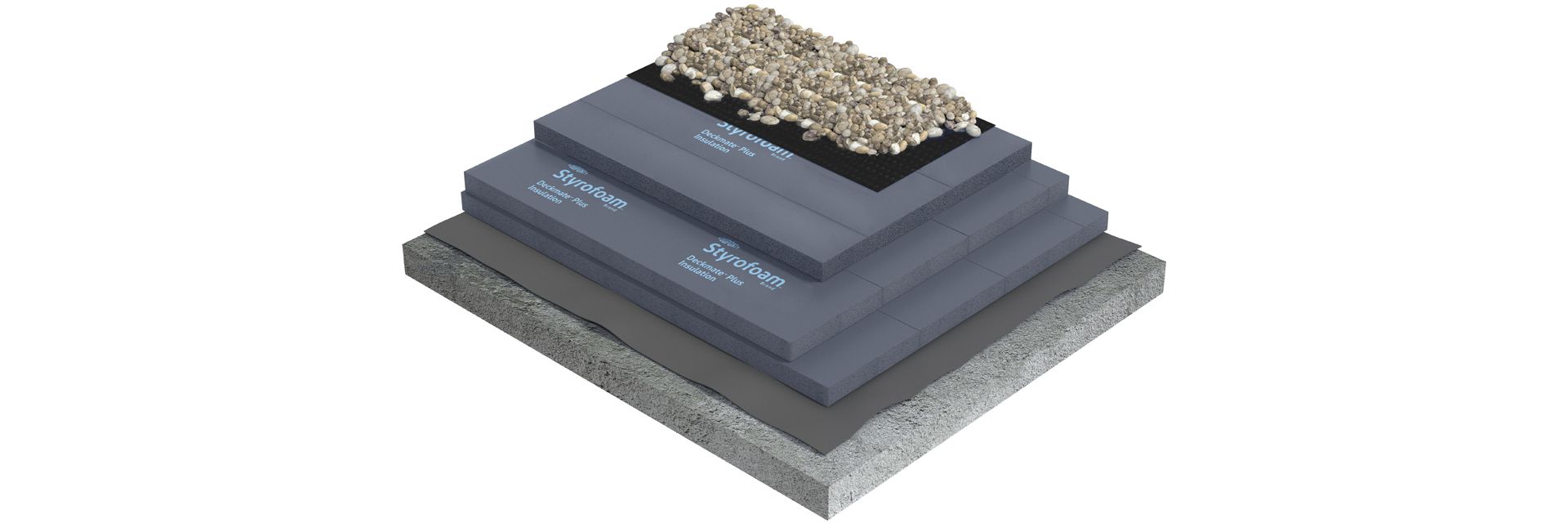

The 200 Larkin Building’s 133,200-square-foot roof had formerly been an inverted or protected membrane roof (PMR) design. In this roof type, the membrane is beneath the insulation. A filter fabric and loose-laid gravel ballast then form the top two layers. Taking advantage of the opportunity to use its own building as a field laboratory, the DuPont Performance Building Solutions (PBS) team directed the roofing contractor to convert one-half of the 200 Larkin roof to a conventional design during the re-roof project, replacing four inches (or two layers) of insulation with a full six inches (or three layers) of new grey reduced-GWP Styrofoam™. The conventional roof design involves the membrane installed on top of the insulation with gravel ballast on top. Having both types of roof designs allows for direct comparison of the two insulation types in the years to come.

Watch the time lapse video of the 200 Larkin re-roof project.

Designing for Reuse

Taking advantage of the ability to reuse the blue board removed from the 200 Larkin roof, it was applied to the neighboring 100 Larkin building conventional roof design. Adding a third layer of insulation also increased the R-value to 30.

What we’re

made of

Styrofoam™ Brand Deckmate™

Made to reduce the harm of freeze-thaw cycles and helps maintain a steady temperature in roof membranes.

Styrofoam™ is transitioning from blue to grey

We have reformulated Styrofoam Brand XPS to reduce global warming potential (GWP).

Protect all six sides of your building envelope

DuPont is your single source for complete building envelope protection.

Commitment to Sustainability

In order to help combat climate change, both regulatory and voluntary building standards are targeting zero carbon emissions and improved life cycle analysis for materials used in North America.

From the experts

Shawn Hunter, Global Sustainability Director

DuPont Performance Building Solutions & Corian™ Design

Learn about embodied carbon and our 2030 sustainability goals.

Sustainability highlights:

- Increased roof insulation thickness and associated R-value by 33%, providing greater thermal, moisture and air management benefits to the building envelope and reducing heating and cooling needs

- A significant amount of roofing material was diverted from landfill, including existing membranes and nearly 70,000 board feet of virtually intact XPS insulation

- Improved energy efficiency inherently mitigates impact of operational carbon

- Reduced-GWP Styrofoam™ Brand XPS reduces embodied carbon without sacrificing the product’s long-term thermal performance, moisture resistance, compressive strength or other critical attributes

A Project of Historical Significance

Beyond serving as the site of the inaugural application of DuPont’s reduced-GWP Styrofoam™ XPS, the Larkin buildings are also where much of the last 80 years of Styrofoam innovation has taken place. The tree-shaded campus stands not far from the physics laboratory and manufacturing facility in Midland, Mich., where the original extruded polystyrene foam was developed in 1941 and where it was produced for many years.

*R means resistance to heat flow. The higher the R-value, the greater the insulating power.

![]()

Designing to a higher standard

DuPont PBS has committed to an aggressive 75 percent reduction in GHG emissions by 2030, compared to 2019 figures. The commitment relies on both reducing embodied carbon through product innovations, but also continuing to mitigate the long-term impacts of operational carbon. Insulation product reformulations (such as Styrofoam™ Brand XPS and HFC-free Froth-Pak™) are part of the company’s “Acting on Climate” goal to achieve a 30 percent GHG reduction in its operations over 10 years and carbon neutrality by 2050. These actions also implement DuPont’s Integrated Energy Strategy to address all sources of GHG emissions, including efforts to create low-carbon industrial processes, source low-carbon materials, and renewable energy, and reduce overall energy use.

See what's trending...

Knowledge you can build on

DuPont Building

Knowledge Center

Keep up to date with the latest information on the products that matter most to your projects

Any questions?

The Styrofoam™ Brand was the original, creating the product segment. Rooted in innovation, we’re excited to deliver a more-sustainable solution. Let’s start a conversation and discuss your next project.Keep learning. Keep building better.

Sign up for updates from DuPont Performance Building Solutions and we'll keep you current on the latest building insights and training opportunities that will help you to do your best work for your customers.