Residual oils and contamination on Nomex® vs. FRT cotton/nylon

Article

Regulations that promote proper cleaning of protective equipment

To benefit from the full protection offered by flame-resistant personal protective equipment (FR PPE), care must be taken to ensure that the garments are maintained and laundered properly. Residual flammable contamination remaining on an FR PPE garment can increase burn injury to the wearer if exposed to a thermal event.

In fact, Occupational Safety and Health Administration (OSHA) regulations require employers to oversee the care and maintenance of FR PPE, even when home laundering is chosen as the means to clean garments used as personal protective equipment. OSHA issued a Letter of Interpretation addressing a question to responsibility for the proper care, maintenance, useful life and disposal of the PPE.

OSHA states to comply with 1910.132 or 1926.95, the employer can allow home laundering, but the employer cannot simply instruct employees to follow manufacturers' instructions.

Full compliance requires employers to:

• Ensure that protective clothing such as FR garments are adequately maintained.

• Ensure the FR garment is laundered so contaminants will not affect the performance of the garment.

• Inspect the clothing on a regular basis to ensure that it is not in need of repair or replacement.

• Train their employees in proper laundering procedures and techniques, if employers rely on home laundering.

• Take responsibility for laundering the FR and arc-rated clothing if all of the above conditions cannot be met.

Overcoming contamination

Some PPE applications and work environments can be more challenging to the garments than others. For example, oil and gas exploration activities commonly result in soiled workers’ FR PPE garments. A common reason FR garments are disposed of after only months of use is due to embedded soil and garment wear.

In these situations, it is important to understand the nature of the contaminants and how these cleaning challenges can be overcome. A critical part of a site’s hazard assessment, required by OSHA, is understanding these challenges and choosing the best FR PPE option to mitigate potential laundering failures.

Performance differences after decontamination

“Nomex® fiber retained the lowest amount of contaminants…”

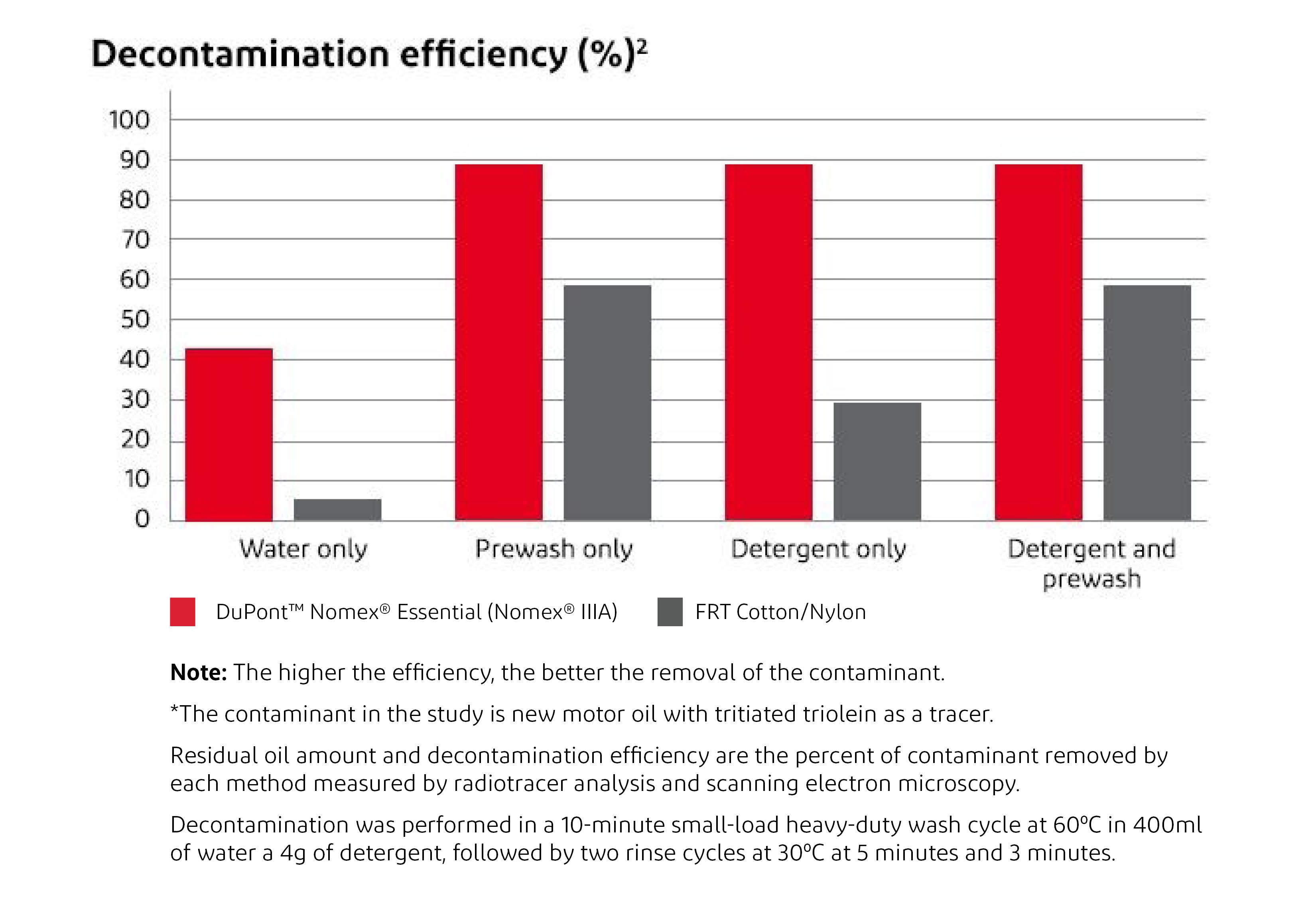

An independent university conducted a study1 to determine the differences in residual oil distribution on and in the fibers of a garment after contamination and decontamination, comparing Nomex® to other common FR fabrics.

The results concluded that the Nomex® fiber retained the lowest amount of contaminants, while the FRT cotton/nylon fiber retained the highest amount of contaminants.

Since oil and other contaminants sit on the surface and do not penetrate synthetic fibers like Nomex®, they are more easily removed.2

While no flame-resistant garments should be used while they are contaminated with flammable material, synthetic materials like Nomex® will release soils more readily than FR garments made from cotton.2

Nomex® never quits

- The highly crystalline structure of Nomex® leads to more soil resistance.2

- Oil on the Nomex® fibers stays on the surface.

- The conclusions of the study were the same even after five contamination/decontamination cycles.2

- Back-scattered electrons (BSE) images show that in addition to oil between the cotton fibers themselves, the oil penetrates the FRT cotton fiber (lumen) and is difficult to remove, regardless of the laundry method.2

Nomex® for ease of decontamination

Regardless of the specific conditions of a worksite, proper cleaning and care of FR PPE is needed to maintain the full protective performance of the garment. When choosing PPE, consideration of the ease of laundering and care can be beneficial to the overall success of the PPE program and worker safety.

For guidance on the use and care of Nomex®, download our Nomex® Laundering Guide.

References

1. The independent study was conducted by the Department of Human Ecology, University of Alberta.

2. Mettananda, C.V.R. & Crown, E.M. (2009). Quantity and Distribution of Oily Contaminants Present in Flame-resistant Thermal-protective Textiles. Textile Research Journal 2010 80: 803. Published Online. DOI: 10.1177/0040517509346439.

*CAUTION: This particular contaminant may not mimic soils in every situation. Flame-resistant protective garments need to be free from any flammable contaminant.