Goal:

_____

Align 100% of our innovation portfolio to meaningfully advance the UN SDGs and create value for our customers

Roadmap to 2030

As we work towards our 2030 objectives, we focused our efforts in 2020 on:

01

Prioritizing SDG challenge areas in early-stage marketing and innovation processes

02

Sharpening alignment of the SDGs with market drivers for our innovation platforms

03

Enacting partnerships for scalable impact to advance the SDGs

The spread of the COVID-19 virus escalated to the level of global pandemic in March of 2020, leaving many healthcare facilities and essential service facilities without the protective gear they needed to battle the deadly virus. As a global leader in personal protective equipment (PPE), DuPont Water & Protection played a vital role in ensuring the world had the materials necessary to fight the virus.

Once we understood the severity of the issue, our purpose — to empower the world with the essential innovations to thrive — became our mandate, and our businesses answered the call. We collaborated with customers and across industries to support development, production, and delivery of the medical supplies and protective equipment necessary to fight the virus and protect our healthcare workers.

Over 100 million protective garments

In April 2020, we launched the #TyvekTogether program to increase the overall availability of Tyvek® personal protective garments worldwide. By the winter of 2020, together with our value chain partners we had produced over 100 million Tyvek®, Tychem® and ProShield garments.

In April 2020, our businesses increased production to support demand for essential healthcare equipment. In some cases, we worked with customers to finalize designs and meet the sharp spike in demand for ventilators, respiratory masks, face shields, and other life-saving items like silicone lubricants for medicine delivery devices.

Our Interconnect Solutions business helped fulfill the urgent need for rigid and flexible circuits to use in ventilators, and ramped up production of Pyralux®, Riston®, and metallization materials to support production of printed circuit boards.

Ask any scientist why they got into science in the first place, and they’ll likely say because they were curious about the world around them and wanted to have a role in changing it for the better. For inspiration on creating that change, we look to the UN SDGs to see the collective, global challenges we face that need to be solved now. Then we dig deeper to ask, “What is DuPont able to contribute to the effort?”

Applying our science and innovation to the SDGs and working closely with our customers helps us forecast what the biggest market drivers will be in the years to come and chart a clear path ahead for our businesses. In 2021, we re-aligned some of our businesses, creating innovation platforms that will help us better apply sustainable solutions to address valuable and important societal challenges.

Today our Electronics & Industrial (E&I) and Mobility & Materials (M&M) businesses are working together offer customers solutions to meet their strong and fast-growing demand for polymeric thermal management solutions for this 5G era. Our range of technologies includes products that are essential to advanced semiconductor packaging such as metallization chemistries, dielectrics, and imageable materials. We also provide assembly materials for advanced semiconductor packaging applications, such as bumping, copper pillars and redistribution layer (RDL), passivation, under bump metallization (UBM), thermal interface, and lid seal adhesion.

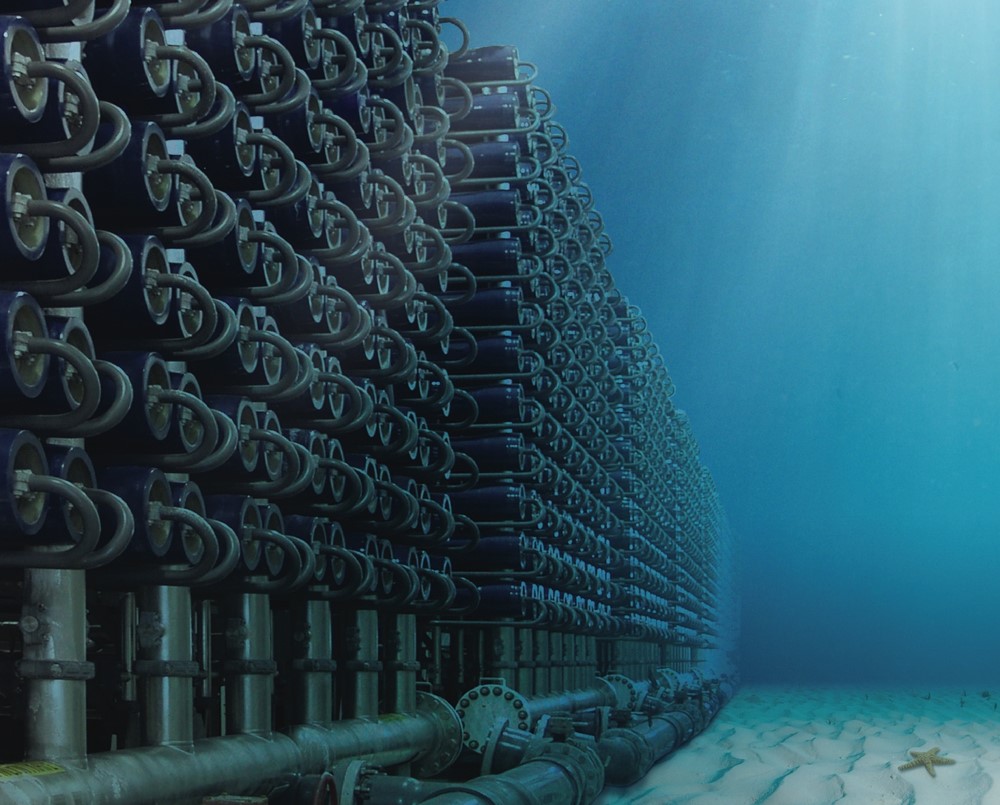

DuPont Water Solutions provides water filtration and purification technology to industrial operations, seaside businesses, and drought-stricken communities. Our DuPont Performance Building Solutions & Corian® Design businesses provide productive, sustainable and resilient high performance solutions for residential and commercial buildings worldwide.

In 2020, DuPont Performance Building Solutions (PBS) and Corian® Design released business-specific 2030 Sustainability Goals. These goals are aligned within the framework of DuPont’s corporate 2030 Sustainability Goals and seek to contribute to the United Nations Sustainable Development Goals (SDGs).

Learn about our PBS and Corian® Sustainability Goals here →

In line with our 2030 goal, we want to develop a company-wide, integrated portfolio assessment program that builds on each business’s respective Life Cycle Assessment (LCA) capabilities. All of our products go through extraction to end-of-useful-life environmental, health and safety assessments as part of our product stewardship review process, and each business is enhancing its LCA capability.

For example, as DuPont Mobility & Materials develops and refines our adhesive products, the team uses an assessment tool that evaluates elements of product sustainability early in the product design and development process. This tool addresses questions such as toxicity, value chain process safety, greenhouse gas emissions, and raw materials choices that would be needed to make the product. The tool also evaluates the potential for the commercialized adhesive to support measures to address global challenges, including the needs of citizens in emerging economies. The aim of the tool is to enable more sustainable choices in product development and design.

In 2020, we added increased our in-house LCA expertise so that we could conduct life cycle assessments of technology and processes in our resins and polymers portfolios to improve the sustainability and circular economy focus of the business.